There are a number of things to do when it comes to the electrical system. When I read the March 2022 survey, I was initially alarmed by all of the urgent recommendations in red. But as the totality of the survey began to gel in my mind, I realized that many of the recommendations amounted to the same thing: provide overcurrent protection near the source.

From the survey, here are the electrical-related issues marked as urgent due to safety concerns:

- Fuel tank is not grounded. Ground fuel tank.

- The fuse panel does not have over-current protection on wire from power source. Install fuse within seven inches of source of power.

- Wiring connected to rear of battery switch does not have over-current protection. Install fuse within seven inches of source of power.

- Wiring connected to battery charge relay does not have over-current protection. Install fuse within seven inches of source of power.

- Wiring connected to batteries do not have over-current protection. Install fuse within seven inches of source of power.

- Wire connected to starter with no over-current protection. Install fuse within seven inches of source of power.

- Battery cable connection to starter is not covered. Install rubber boot over terminal.

- Black and red wires, near battery charge relay connected with lug. These wires need identified and connected to terminal strip.

- A/C main circuit breaker panel does not have double pole circuit breakers. New A/C panel needs to be installed, which has double pole main circuit breaker, voltmeter, and ammeter, and reverse polarity warning light.

- There is no reverse polarity indicator or ammeter/ volt gauge. See above.

There were other issues found that were not as urgent, including:

- Too many ground wires are connected to engine block and connections are corroded. No more than four wires should be on one terminal. Install terminal strip and attach wiring.

- Ground terminal at fuse block has too many wires connected to it. No more than four wires should be on one terminal. Install terminal strip and attach wiring.

- Some wiring is not marine grade stranded wire. Replace all wiring that is not marine grade stranded wire.

- Battery cables are welding wire. Replace battery cables with marine grade cables.

- Batteries have wing-nuts on connections. Replace wing-nuts with hex nuts.

It’s important to note that many issues identified in the survey did meet ABYC standards when the boat was built in 1982. Standards may change over time, and they did, so that’s why several of the survey recommendations were made.

Planned actions

| Problem | Solution | Timeframe | Notes |

|---|---|---|---|

| FUEL TANK | |||

| Tank is not grounded | Ground the tank | July 2022 | Mast is bonded to keel. Will do same for fuel tank. This? |

| OVERCURRENT PROTECTION | |||

| Fuse panel lacks protection | Add fuse | July 2022 | And replace panel w/ larger or same size |

| Battery switch lacks protection | Add fuse at source | July 2022 | |

| Battery charge relay lacks protection | Add fuse | July 2022 | Consider this fuse block |

| Batteries lack protection | Add fuse at terminal | July 2022 | Terminal fuse for each battery might be good solution |

| TOO MANY… | |||

| Too many ground wires on engine | Install terminal strip | July 2022 | |

| Too many grounds on fuse block | Install terminal strip | July 2022 | Small 4-circuit terminal strip |

| Wing nuts on batteries | Replace with hex nuts | July 2022 | |

| MISCELLANEOUS | |||

| Starter terminal uncovered | Add protective boot | July 2022 | Automotive part |

| Wires connected with lug | Add terminal strip | July 2022 | |

| 120V AC CIRCUIT | |||

| AC breakers are not double pole | Evaluate | August 2022 | Additional evaluation of the AC circuit is needed |

Fuel tank

On top of the fuel tank is a tab with a hole drilled in it. I assume is a bonding lug. In any case, that’s what I plan to use it for!

The sending unit installed in the tank for the fuel level is not working: the gauge always measures just below 1/2 full. It looks like it is a Moeller gauge so I may be able to do a simple remove-and-replace job to fix this problem.

Unrelated to this electrical projects post: the tank needs to be cleaned outside (and probably inside). The fill hose looks to be original from 1982 so replacing that hose is indicated sooner rather than later!

Battery

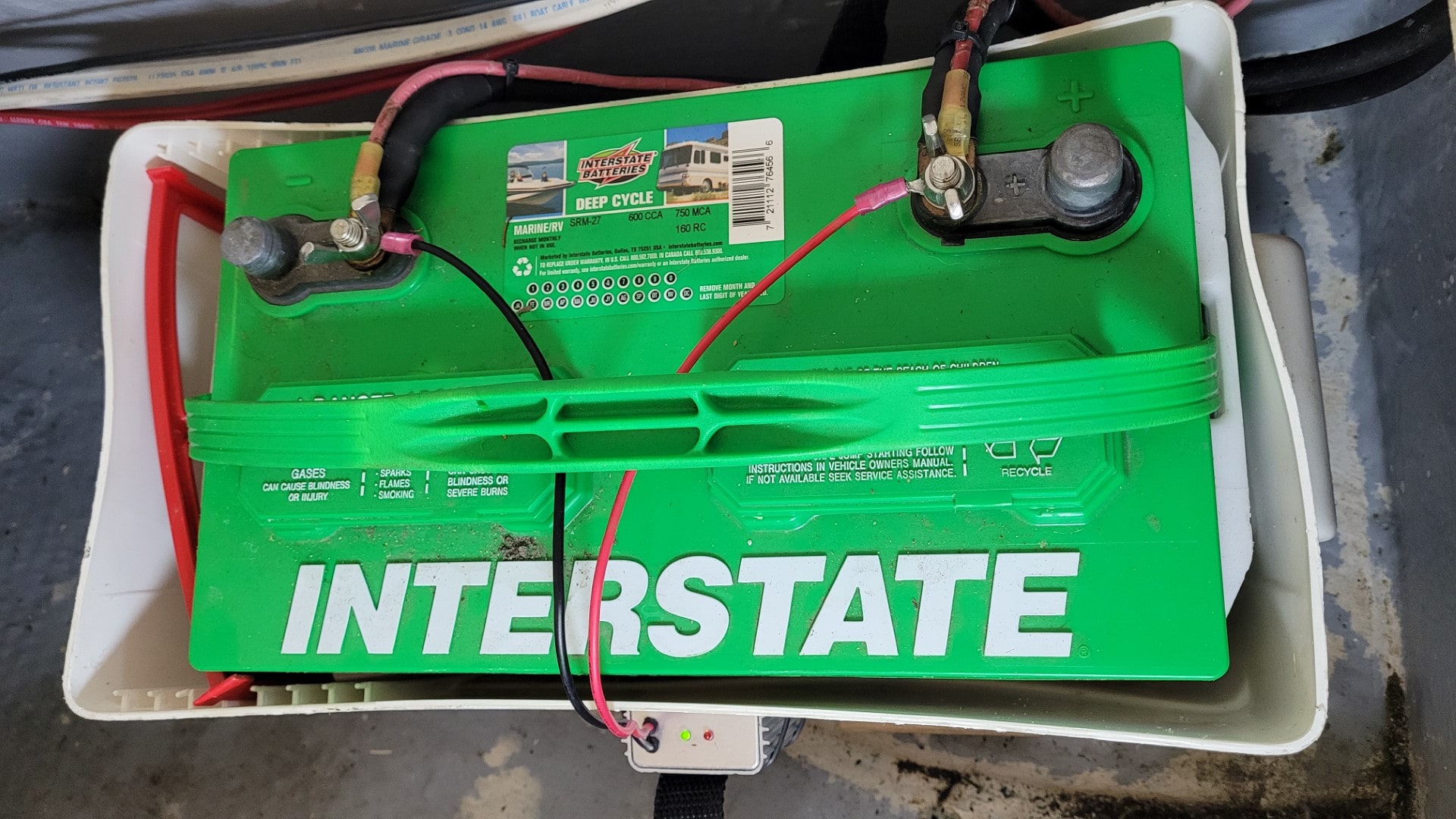

Battery #1 looks to be in good condition. The water level in the cells was full to almost full with no plates exposed. There are cleats installed that prevent the battery from moving around, and unlike what I saw in some other older boats, the battery is in a box.

I am researching whether to upgrade the batteries. I’d prefer AGM or gel cell batteries for easier maintenance, and I wonder if the additional capacity and life of Lithium Ion batteries would be worth the added expense.

AC circuit

The AC circuit is not complex but it is a bit problematic. I have 30 amp service to the boat. That service is split into two 15 amp circuits on the boat. The survey recommends changing the two single pole breakers to double pole breakers. This confuses me because, in my limited experience, that would normally be configured as a 230V circuit, similar to what you might use for a clothes dryer or electric water heater.

I need to talk to an electrician. Sure, I could use double pole breakers, but they would have to operate independently in order to provide 120V on each subcircuit. How is that different than what already exists with the two single pole breakers?

I finally cleared the port quarter berth to access battery #2. Water levels in the cells is slightly lower than in battery #1 but no plates are exposed. I’ll add distilled water to both batteries in June.